-

Yuhuan Qianhuan

Yuhuan Qianhuan

Plastic Industry Co., Ltd. -

Get Call Us:

Get Call Us: -

E-mail:

E-mail:

| Capacity | Upper diameter | Lower diameter | High |

|

750ml

|

145

|

110

|

81

|

|

Drop cup mouth

|

Weight

|

Minimum order quantity

|

|

|

117

|

58

|

30000

|

|

| Capacity | Upper diameter | Lower diameter | High |

|

680ml

|

123

|

100

|

104

|

|

Drop cup mouth

|

Weight

|

Minimum order quantity

|

|

|

115

|

49

|

30000

|

|

| Capacity | Upper diameter | Lower diameter | High |

|

750ml

|

145

|

110

|

81

|

|

Drop cup mouth

|

Weight

|

Minimum order quantity

|

|

|

117

|

58

|

30000

|

|

|

Upper diameter |

Lower diameter |

Height |

|

148 |

128 | 150 |

|

Weight |

Minimum order quantity |

|

|

88.5 |

50000 |

|

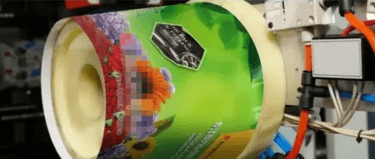

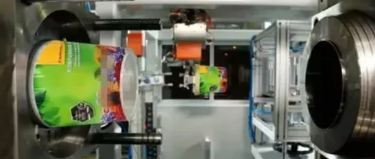

In-mold labeling is a brand new label packaging form different from the traditional direct screen printing, thermal shrinkage label, self-adhesive label, because the in-mold label and Plastic Chocolate Buckets naturally integrated, so there will be no blister, wrinkle and other phenomena. So the IML printing exquisite, can do laser, aluminum plating and other special treatment, so that the product packaging grade greatly improved. Most of our products use IML technology, customers can customize the design or provide thelabel by themself, we sell quality Plastic Chocolate Buckets at wholesale price.

Firstly, before blow molding or injection molding, put the printed label inside the blow molding cavity.

Secondly, When the mold is closed for blowing and injection, the special adhesive on the label in the mold is melted through the action of high temperature and high pressure in the mold.

Thridly, the surface of the bottle or injection parts is fused into one body. When the mold is opened, a bottle or injection part that has been beautifully printed is finished in one time.

Play Video

Play Video